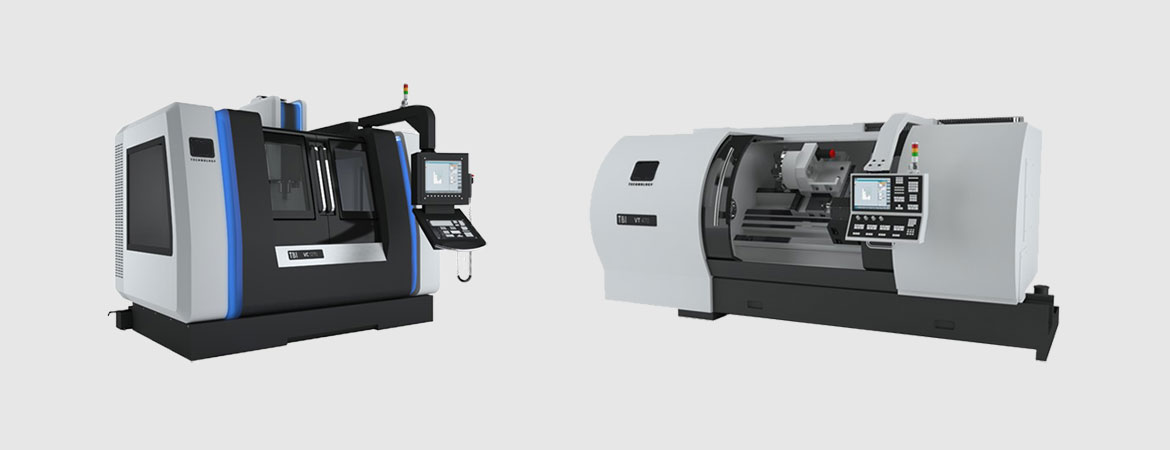

Obróbka Skrawaniem - Frezowanie (zdjęcia)

(+48) 576-876-044

Hours: 9am-7pm PST M-FrFree Shipping

- CategoriesNew!

- SpecialsSale!

- Quick Links

- Manufacturers

- Info

- Shipping & Returns

Shipping

The delivery of goods is carried in Poland, the European Union, Great Britain and selected countries outside the European Union and is carried out by the courier company DPD or DHL. Delivery of goods to the recipient from Poland for orders over €499,00 is free and carried out by the route chosen by the Ordering Party during the ordering process. Below this amount, the shipping costs are covered by the Ordering Party, in accordance with the table presented in the shipping cost estimator. For recipients from outside Poland, the delivery of goods for orders over €499,00 is free and carried out by the route chosen by the Ordering Party during the ordering process. Below this amount, the shipping costs are covered by the Ordering Party, in accordance with the table presented in the shipping cost estimator.

Returns

The return is allowed only in the case of unchanged goods and applies only to CONSUMERS (i.e. natural persons, not conducting business activity). The deadline for the return is 14 days from the receipt of the goods by the Ordering Party. The ordering party should send the goods to the address of the company MaXXaM SP. z o.o. on the page www.maxxam.com.pl. The Orderer shall bear the costs of delivering the returned goods. The company MaXXaM Sp. z o.o. within 14 days of receiving the returned goods, he will return the money to the account of the Ordering Party from which the payment was made.